| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | YES |

| Model Number : | YES-1 |

| Certification : | CE ISO RHS |

| Payment Terms : | T/T, L/C, Western Union, MoneyGram |

| Supply Ability : | 300 sets per month |

| Delivery Time : | 1 days after payment received |

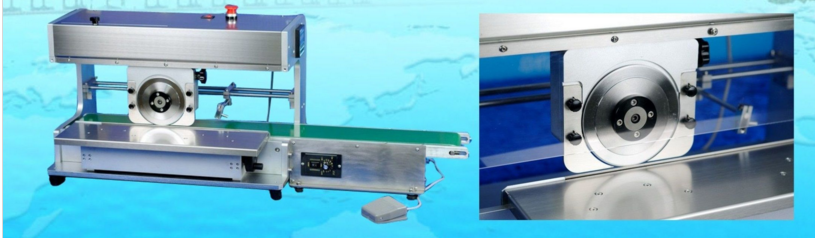

PCB Depaneling Machine With Safe Sensor PCB Separator For PCB Assembly

Main points of the programmable PCB Separator YES-1

Any more details you are welcome to contact us and visit our pcb

depaneling machine warehouse

1. The machine cut PCB boards without damaging electronic

components. And it can improve efficiency.

2. With blade moving, it can reduce pressure on board to avoid

solder joint crack and parts fracture.

3. Upper circular blade cuts against lower linear blade to separate

PCB board, smooth and clear cuts.

4. Set fixed start and end point for blade moving according to the

length of PCB.

5. According to the width of PCB, the back baffle can be adjustable

from 0 to 150mm.

6. The blades are sharp and indurable. And they can be sharpened

between 7 and 10 times.

Customers FAQ About PCB Separator YES-1:

1. Q:Do you have any certification for this machine?

A:YES,We have CE ISO FCC ROHS etc.

2. Q:What is warranty of the machine?

A:1 year.

3. Q:How do you pack the machine?

A:We fix the machine on the plywood base with screws to ensure safe

transportation.

4. Q:What is life time of machine blades?

A:About 6-12 months.

5. Q:What is material of blades?

A:Japan high speed steel SKH-9

6. Q:Can the blades be sharpened?

A:Yes, they could be re-sharpened for 2-3 times.

7. Q:How do you offer oversea service?

A:We could send engineer to do installation and training for client

if needs.

8. Q:Can we see your machine in our country?

A:Yes, we would like to offer contact details of our clients who

are using our machines.

Any other questions or confusion please contact our pcb depaneling salesman mail or directly call us.

V Cut PCB Depaneling machine Technical:

| Model | YES-1 |

| Max. PCB singulation length | 460 or 600 mm(on request custom made) |

| PCB singulation thickness | 0.6-3.5 mm |

| PCB singulation feed rate | 100,200,300,500 mm/sec |

| Blade motion | upper circular blade moving automatically |

| Blade motive power operating mode | motor-driven |

| Power supply | 110/220v |

| PCB singulation machine size | 770*510*450mm |

| PCB singulation machine weight | 55kg |

Why Clients Buy Our PCB Separator Model YES-1

1. It is safty, Separates large numbers of PCBs without fatigue of

the operator

2. Motor driven

3. The PCB is feed between the circular blades where it is seized,

transported and separated

4. Different speeds can be selected

5. We can made plate according the customers requirement .

1, solid operating agencies, to prevent improper external force

caused by the PC tin pavement reflow, solder circuit damage.

2. Linear rolling oppressive cut V-trough plastic plate or various

types of fiberboard, completely prevent the damage of the solder

joint and fracture, special lines of code slide cut to ensure that

the cut surface smoothness, cutting the travel distance take five

touch adjustment can be divided into four stroke, to facilitate the

best use of flank wear, the machine is equipped with two speeds,

one way to return the way cut off for selection.

3, install anti-cut fingers electronic eye protection devices, to

avoid people who do not hurt.

4, the lower part of the configuration of the platform to end the

fluorescent light, to prevent the work of errors in the playground

in the shadow environment

Our Service:

who was directly ordered from the company pipe cutting machine /

cutting machine / cutting machine / cutting machine products, the

whole year warranty, the motherboard free of charge warranty of

three years are entitled to a permanent after-sales service freight

logistics: choosing the fastest formal logistics companies, and

full attention to the machine to the situation.

|